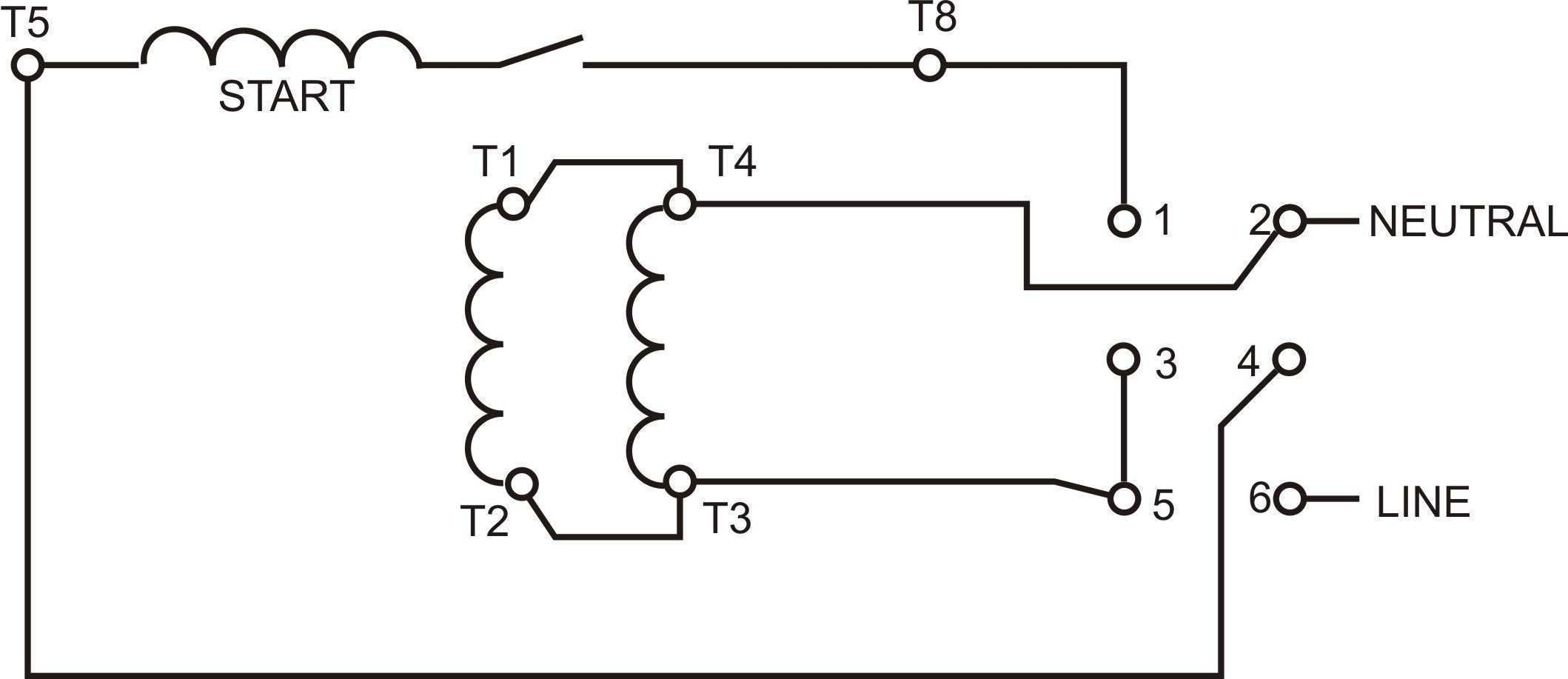

The electrical drawings shown below illustrates a standard 12 leads wiring connection for induction motors rated with dual voltage functionality in star (wye) configuration.įig-1: 12 Leads 3 Phase High Volts Star (Wye) Connected Motor Configuration It is also a standard practice for motor manufacturers to provide information about the motor's specific wiring connection for both low and high voltages on the motor's nameplate or on the cover of the motor's terminal box.Įach of the rated voltage values intended for the motor's operation requires different methodology of wiring connection in order to run the motor in either low or high volts operation.

The rated operational voltage of any induction motors can be found from the motor's nameplate. The motor will have to be appropriately selected accordingly, which is basically dependent on the application for which the motor is intended to operate based on the available source voltage where the motor is to be installed.įor the purpose of providing an example, the most common operational voltage for induction motors in most industrial application are motors designed to operate with 220 and 440 volts power supply.

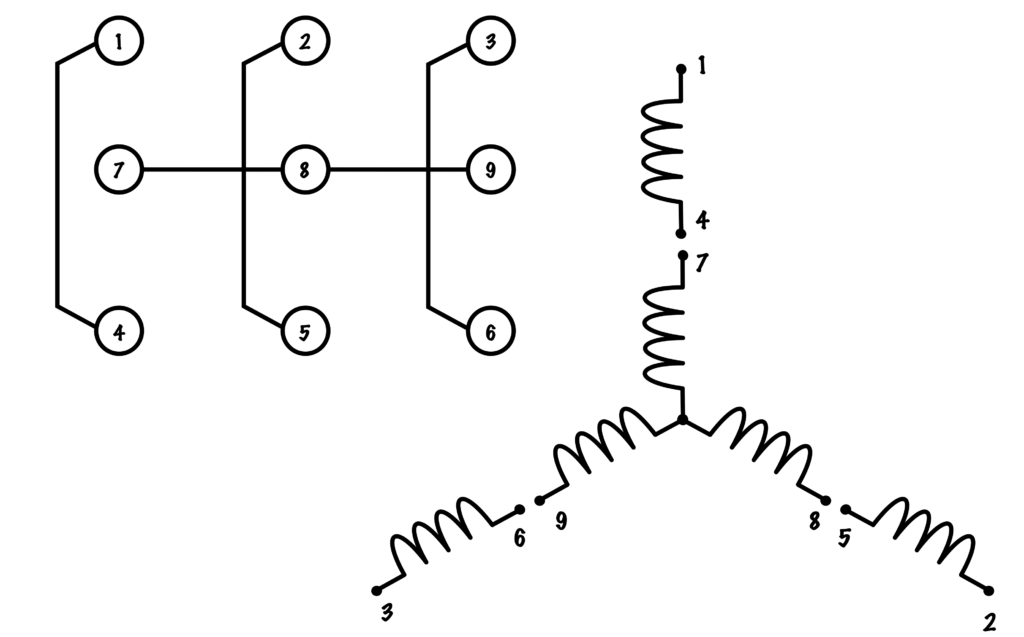

This means that the motor was specifically designed for dual voltage operation which can be supplied with either low voltage or high voltage configuration. This can be determined directly by counting the number of available terminal leads accessible from the induction motor's terminal box.Īll 12 leads motors are most commonly made for dual voltage application. Another convention of wiring connection for the AC induction motor apart from the 9 leads and the widely known 6 leads terminal is the 12 leads motor wiring connection.

0 kommentar(er)

0 kommentar(er)